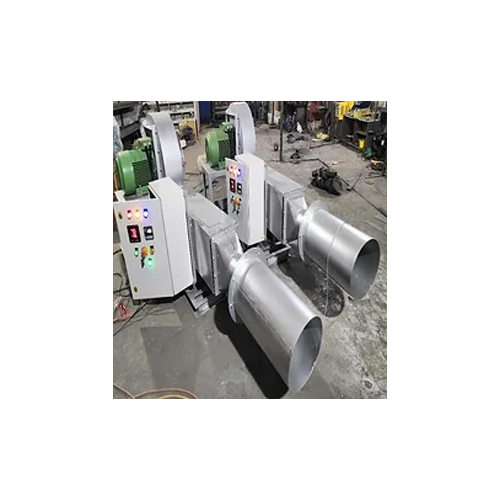

Hot Air Blower

Product Details:

- Usage To Dry the material via Hot air process

- Height 650mm Millimeter (mm)

- Product Type Centrifugal Hot Air Blower System

- Weight 250kg Kilograms (kg)

- Color As per client Request

- Width 800mm Millimeter (mm)

- Length 1500mm Millimeter (mm)

- Click to view more

Hot Air Blower Price And Quantity

- 1 Piece

- 65000.00 INR/Unit

Hot Air Blower Product Specifications

- 800mm Millimeter (mm)

- 650mm Millimeter (mm)

- As per client Request

- To Dry the material via Hot air process

- 1500mm Millimeter (mm)

- Centrifugal Hot Air Blower System

- 250kg Kilograms (kg)

Hot Air Blower Trade Information

- EXW

- Western Union, Cheque, Telegraphic Transfer (T/T)

- 3 Piece Per Week

- 7 Days

- Yes

- If order is confirmed we will reimburse the sample cost

- wooden Box/as per client request

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- ISI MARK / ISO CERTIFICATION / CE CERTIFIED / TRADE MARK CERTIFIED / MSME CERTIFICATE / GEM SELLER CERTIFICATE / IMPORT EXPORT CERTIFICATE

Product Description

Hot Air Blower- Hot air electric blower, Portable hot air blower, Hot air centrifugal blower

To expedite a variety of manufacturing processes, choose a sturdy industrial hot air blower.

A machine called an industrial hot air blower is used to supply hot air for many industrial activities. It has blades and an impeller powered by a centrifugal blower, which moves air from one place to another. It is employed for many purposes, including drying out coatings, heating pieces in a production process, deflashing plastic products, and heating a specific area. In order to generate air movement, they can generate both positive and negative pressure around their blades.

What Makes Purchasing an Industrial Hot Air Blower a Good Idea?

In order to accomplish a certain goal, heated air is blasted at a high speed using a hot air blower. When air is forced through impellers in a general air blower, its velocity rises. This kind of blower is employed in aspirating, conveying, ventilating, and cooling operations. Applications requiring a regulated air focus greatly require these devices. The same procedure is used in a hot air blower, except the air passes through a heated element instead. As a result, it raises its temperature before being sent out in this manner to have the required impact on the application. Operates, but a heated element is used to pass the air through. As a result, it raises its temperature before being sent out in this manner to have the required impact on the application.

The temperature of an air blower manufactured by Vayuvents Private Limited is one of its most crucial characteristics. Having an on-board thermocol to measure the temperature is essential in situations where it needs to be monitored so that modifications can be made as needed. Since this gadget comes in a wide range of sizes, a little one is required. You might check into a device that has airflow settings because there are some situations where high or even low air flow is required.

How is a heat blower used?

There are several kinds of blowers, each with a distinct function. But regardless of the type you select, the overall purpose is the same. With the right temperature and airflow settings (which vary depending on the application and goals), you may use a blower to guide airflow to the desired location.

Process Heating: What Is It?

Process heating is a technique that raises the temperature of any material-solid, liquid, or gas-that is being handled with. After that, the heated substance is worked as needed. It has the ability to melt, soften, or even evaporate. A chemical reaction, molecular disintegration, or molecular rearrangement follows.

Process heating can be accomplished with a variety of tools, some of which are better suited for particular jobs than others. For instance, thermal processing equipment helps with material drying and microbial reduction, making it the preferred option for those working in the food industry.

All heat processing technologies ultimately deliver the same function, although having different uses: heat. Fuel oil, natural gas, and, in the case of the tools you will discover on this website, electricity are some of the sources of this heat.

Many different businesses use process heating in their industrial processes. The list is endless and includes automotive, jewellery, pulp & paper, packaging, and aviation. Additionally, companies of all sizes use heat processing equipment; it's not just the biggest companies that do it.

Specifications -

Temperature range: 30oC to 650oC

One of India's top and most reliable producers and suppliers of industrial hot air blowers is Vayuvents.

There are several uses for industrial hot air blowers, including:

1. Dry parts and coatings.

2. During the production process, warm up a specific area.

3. Heating components to expedite the manufacturing process.

International industrial norms were taken into consideration during designing. with an emphasis on superior durability and quality.

Which industrial hot air blower features are the best?

- Small in size.

- RTD sensor for precise temperature detection;

- Insulated heater housing.

- Available in a range of parameters.

- Ideal for quickly heating and drying parts or materials.

Easy to use, floor mounted for open area application, trolley mounted for portability and ease of carrying, digital temperature meter, extractive design and blower overload protection.

What uses do industrial hot air blowers have?

The following industries are included: food, chemical, textile, packaging, automotive, and mechanical engineering sector

FAQs of Hot Air Blower:

Q: What is the usage of Hot Air Blower?

Q: What type of material is used to manufacture the Hot Air Blower?

Q: What is the temperature range of Hot Air Blower?

Q: What is the power consumption of Hot Air Blower?

Q: What is the weight and dimension of Hot Air Blower?

Q: What is the voltage requirement of Hot Air Blower?

Q: Does Hot Air Blower come with an alarm system?

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese