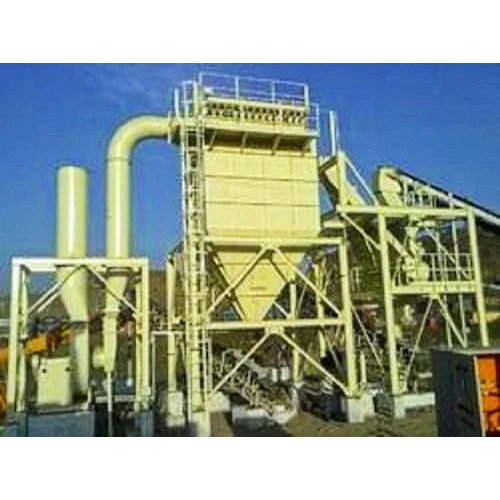

Dust Collector

Product Details:

- Usage & Applications Industrial

- Product Type Dust Collector

- Material Mild Steel

- Voltage 415 Volt (v)

- Warranty 1 Year

- Click to view more

Dust Collector Price And Quantity

- 250000 INR/Piece

- 1 Piece

Dust Collector Product Specifications

- 1 Year

- Mild Steel

- 415 Volt (v)

- Dust Collector

- Industrial

Product Description

A powerful filtration system for use in large industrial settings is the pulse jet dust collector.

A pulse jet dust collector is a kind of suck and filter device that draws in dust-laden air, collects the particles, and then releases clean air. This gadget is used to maintain a clean environment, which is essential in an industrial setting. Dust can spread in the air as a result of many manufacturing operations or labour processes in industries. Poor working conditions result from the difficulty of cleaning it up. Using a dust collector is crucial in these kinds of circumstances.

What Advantages Does Using a Pulse Jet Dust Collector Offer?

An intake allows unclean air to enter the pulse dust collector. As the air travels through different filter cartridges, the dust is captured. Then, clean air-which has undergone numerous filtration processes to make it breathable-is released through the outlet. Handling, installing, and removing this item is simple. Because of its excellent filtering efficiency, only pure air is released and even the smallest dust particles are captured. The precise filters required for a given use can be chosen. Customers can purchase accessories for this gadget based on their need.

Workers in dust-filled industrial settings require a great deal of help to maintain a clean working environment. Because it provides immediate respite from dusty settings and creates an environment where work can be done normally, the Vayuvents Private Limited pulse jet dust collector is the best choice in this situation. Dust-laden air is drawn into it, cleaned, and then released back into the environment. This straightforward procedure effectively eliminates some of the worst kinds of dust that are in the air; all of the dust that the filter has captured should be cleaned thereafter to ensure optimal system performance.

It can be utilised in a variety of settings, such as factories, warehouses, commercial settings, and plants. It makes it possible for these establishments to comply with EPA emission regulations and quality safety standards. It is a robust, long-lasting machine that can operate for extended periods of time without breaking down or failing. Processing facilities, fabrication shops, grain mills, and other locations where particulate matter is constantly present are a few examples of where you might observe this equipment in action. Filter Concept is a maker of Pulse Jet Dust Collection systems that improve air quality and meet the needs of different businesses by removing particulate matter from the air and surroundings and collecting dust and other contaminants from petrol or air. We are a manufacturer of highly customised devices that include dust collectors and ducting solutions tailored to your unique dust collection and application needs.

Operation:

Through the inlet, the contaminated or dirty air enters the dust collector and travels through several filter cartridges or bags. Before the contaminated air reaches the filter bag or cartridge, the baffle plate acts as a protective layer to control or retain heavy particles, preventing the filter bags or cartridges from coming into contact with heavy particles and causing damage. This keeps the dust particles on the outside of the bag while letting clean air flow through the outlet. The dust cake that forms from the collected dust as the collector runs eventually reduces the porosity of the filter cartridges. The collector's ventilation volume falls as the pressure drop rises.

The cleaning cycle is used to continuously clean the filter bags and cartridges while maintaining a moderate pressure reduction. The solenoid valve and time controller that operate the solenoid valve and compressed air header make up the cleaning system. High pressure compressed air is briefly released from the compressed air header and enters the filter tube through the blow pipe. The reverse air flow produced by this air pulse causes the filter cartridges to expand, removing the collected dust.

When the dust cake is pulsed from the filter cartridges, it falls straight into the bucket at the bottom where it is cleaned; because the cleaning process is row-by-row, only a portion of the total filter air is interrupted for cleaning, providing for continuous ventilation.

Features and Advantages

- Simple to use, manage, and install and delete.

- Minimal use of compressed air (cleaning).

- Excellent filtration performance, even for the smallest dusts.

- Select medium based on application.

- Accessories requested by the client.

Applications:

- Metals & Minerals

- Steel & Power

- Chemicals

- Cement

- Powder & Coating

- Pharmaceuticals

| Material | Mild Steel |

| Bag Type | Pocket Filter |

| Automation Grade | Automatic |

| Frequency | 50/60 Hz |

| Brand | vayuvents |

| Voltage | 415 V |

| Filtration Efficiency | 99.9% |

| Air Capacity | 8000 cfm |

| Power Source | Electric |

| Country of Origin | Made in India |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese